We are so proud to announce our recent win at the Australian Steel Insititute Steel Excellence Awards for the Buildings: Small Projects QLD & NT Category!

Project: Brisbane Grammar School – STEAM Building (Science, Technology, Engineering, Art and Mathematics)

Entering Organisation: Sencova* Steel Fabricators

Architect: Wilson Architects

Structural Engineer: Robert Bird Group

Head Contractor: BESIX Watpac

Steel Distributer & Manufacturer: Southern Steel QLD; Lysaght; InfraBuild; BlueScope

Steel Fabricator: Sencova* Steel Fabricators

Coatings Suppliers: Valmont Coating, Industrial Galvanizers; Diamond Blast

Design

Pushing the boundaries of design, this multi-story education facility provides students with a transformative learning environment unlike their everyday classrooms; boasting 15 collaborative laboratories, 14 versatile learning spaces, five dynamic design studios, art workshops, and a spacious 300-seat open auditorium.

At the heart of the building lies it’s most striking feature: an expansive atrium housing innovative learning pods crafted from fabricated steel. Each pod comprises of seven structural rings, meticulously suspended from the ceiling and enveloped in transparent glass, giving the appearance of a vibrant “petri dish”.

Engineering

In engineering, longevity is a cornerstone, and the CC3 (Certified Construction Category 3) Project epitomises this principle with its design life extending over 50 years. This ambitious structure incorporates an impressive 333 tonnes of structural steel, setting a high standard for resilience and durability in modern construction.

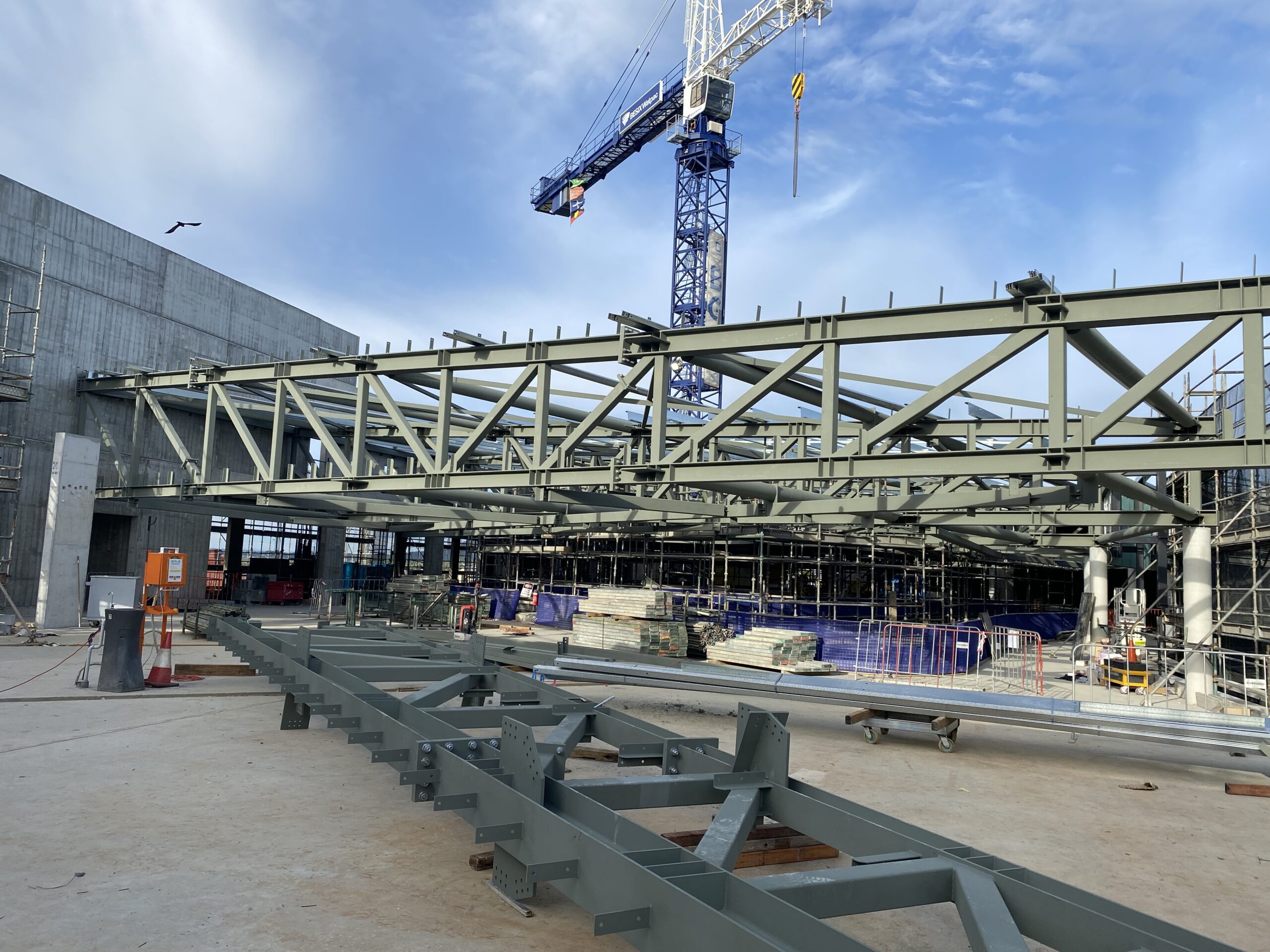

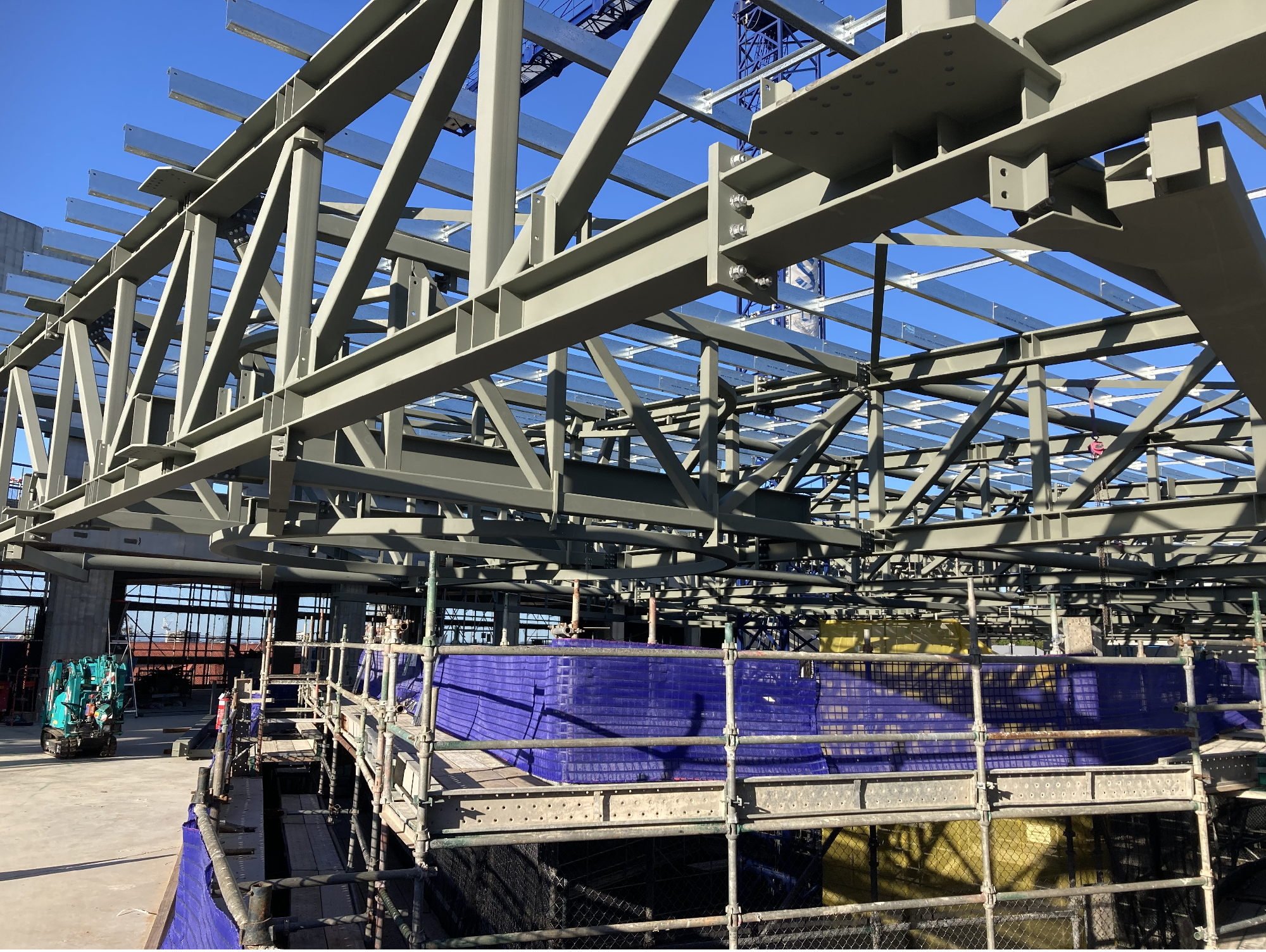

One of the project’s most striking features is its sleek steel pods, which are gracefully suspended above the central atrium, creating a dynamic visual effect that also serves a functional purpose. Complementing this are the cantilevered roof and walkway structures, constructed from long, robust fabricated steel trusses. These trusses elegantly bridge the gap between the old and new buildings, establishing the core of the innovative STEAM Precinct.

The roof’s engineered structure not only provides protection but also integrates a suspended walkway that seamlessly connects the two buildings. This walkway and atrium structure is built to support the hanging pods, symbolizing the project’s blend of cutting-edge design and enduring functionality. The CC3 Project stands as a testament to forward-thinking engineering, crafted to inspire and endure for generations.

Construction Efficiency

The CC3 construction project, ultimately an educational facility upgrade, was designed with a focus on durability, efficiency, and local sourcing. To meet stringent engineering standards and ensure the new and renovated buildings meet contemporary expectations, the project required predominantly Australian steel. This choice was driven by the need for robust, long-lasting structures that can stand the test of time.

Locally sourcing materials was key to boosting efficiency and reducing lead times. The steel used for the project received special treatments, with heavy-duty paint and galvanizing applied for top-tier corrosion resistance and easier long-term maintenance. Notably, Diamondblast Sandblasting & Protective Coaters, known for their high-quality work and reliability, managed the painting process on 90% of the steel used, ensuring it was completed on schedule.

A portion of the steel underwent Hot Dip Galvanizing to provide even more enduring protection. For this, we partnered with Valmont Coatings – Industrial Galvanizers’ Pinkenba branch, whose quality and dependability made them ideal for this critical work.

The proximity of both Diamondblast and Industrial Galvanizers to our workshop played a significant role in the project’s success. This close collaboration allowed for efficient transportation and seamless execution, helping us meet project milestones effectively. Through these combined efforts, the CC3 project stands as a model of quality, resilience, and dedication to local resources.

Environmental Sustainability

Working with premier Australian steel providers, the Sencova Team ensured that all materials met rigorous CC3 standards and contributed to a responsible environmental footprint.

Our main supplier, Southern Steel QLD, a top provider and distributor of Australian steel, played a key role in delivering high-quality materials to the project. Their expertise and reliability helped meet the demanding structural requirements necessary for this long-lasting construction.

Infrabuild, another primary supplier, brought an added sustainability dimension. As a leader in environmentally conscious steel manufacturing, Infrabuild is committed to reducing embodied carbon—a perfect alignment with the CC3 project’s dedication to building responsibly for future generations. To learn more about Infrabuild’s sustainable practices, visit their sustainability page.

We also sourced materials from Bluescope, an Australian manufacturer recognized for its adherence to the Responsible Steel Standard. Bluescope’s vision emphasizes maximizing steel’s role in sustainable development, ensuring that steel production aligns with a greener future. More on Bluescope’s sustainability efforts can be found on their certification page.

Through these partnerships with Southern Steel QLD, Infrabuild, and Bluescope, the CC3 project exemplifies a dedication to both quality and environmental stewardship, building a structure that stands for durability and a sustainable future.

At Sencova Steel Fabricators, we pride ourselves on our unparalleled expertise in steel fabrication, a commitment that shone through in our work on the CC3 project. From the outset, our state-of-the-art facility became the backdrop for meticulous craftsmanship, where we shaped steel to meet precise project specifications. Each step of the fabrication process included thorough quality assessments, with a strong emphasis on material traceability, ensuring that every component met our high standards.

Utilizing advanced techniques such as industrial welding and sophisticated boilermaking, we delivered results that are second to none. Behind the scenes, our dedicated project management and administration teams worked tirelessly to uphold the project’s quality throughout its lifecycle.

Erection

Our commitment to professional on-site steel delivery ensured a smooth and timely installation process. For the erection of the steel pods and roof trusses, we collaborated with Mulherin Crane & Rigging Australia (MRCA), a leading steel erection company in Queensland known for their exceptional professionalism. Their meticulous planning and effective erection methodologies were vital to the project’s success.

With a proven track record of skilled solutions and top-quality workmanship across various projects, MRCA has established itself as a trusted name in rigging and crane operations. Their highly skilled site crews executed the steel erection safely and efficiently, further enhancing the project’s overall integrity.

Thanks to our rigorous quality checks in the workshop and thorough preparation, the final outcome of the CC3 project was nothing short of exceptional. We take immense pride in what we accomplished and look forward to continuing our legacy of excellence in steel fabrication and erection.

From all of the team at Sencova, we would like to express our sincere appreciation to all of our values suppliers for their invable contributions to this project. Without you, this win would not have been possible.

Thank you to:

- Southern Steel QLD

- Infrabuild

- Bluescope

- Lysaght

- Diamondblast Sandblasting & Protective Coatings

- Valmont Coatings-Industrial Galvanizers, Pinkenba branch